The EnCoRe Project: an International Network for Sustainable Concrete

Authors: ENZO MARTINELLI – Università di Salerno (Italy), JOAQUIM A.O. BARROS – Universidade do Minho (Portugal), GUILLERMO ETSE – Universidad Nacional de Tucumán (Argentina), LIBERATO FERRARA – Politecnico di Milano (Italy), PAULA CECILIA FOLINO – Universidad de Buenos Aires (Argentina), EDUARDUS A.B. KOENDERS – Universidade Federal do Rio de Janeiro (Brazil); MicroLAB, TUDelft (The Netherlands) et ROMILDO D. TOLEDO FILHO – Universidade Federal do Rio de Janeiro (Brazil).

Introduction

As well as in other human activities, environmental issues are getting the attention of the building industry more and more. Due to obvious reasons, construction and demolition waste, as well as other industrial by-products, may be used to obtain recycled concrete constituents. For instance, Recycled Concrete Aggregates (RCA) can be produced from existing concrete members that result from either industrial processes (e.g. precast structures) or demolitions of existing structures as a whole. In the latter case, concrete is not the only component of waste, as demolition rubbles of RC buildings also contain other materials, such as steel bars, masonry bricks, wood, plastics, and so on. Moreover, waste resulting from industrial processes other than the building industry could be efficiently disposed of as concrete aggregates as well. Sometimes, similar industrial processes can even produce waste (i.e. mainly made out of either plastics or metals) that may efficiently be employed as dispersed reinforcement, resulting in a class of cement-based materials designated as Fiber-Reinforced Concretes (FRC) or, more generally, Fiber-Reinforced Cementitious Composites (FRCCs). In such cases, the physical and chemical issues concerning the compatibility between the fibers and cementitious matrix, the durability of the resulting material, as well as its mechanical performance, should be thoroughly investigated. A further environmentally-friendly and cost-effective solution for producing FRCCs can be achieved by applying natural fibers as a reinforcement system. The characterization of the key physical and mechanical properties of this novel class of cementitious materials made partly from the aforementioned replacements of recycled and natural constituents is the main goal of the EnCoRe Project (www.encore-fp7.unisa.it), the EU-funded initiative outlined in this article.

Three objectives are addressed:

Objective 1) Predicting the physical and mechanical performance of concrete with recycled aggregates;

Objective 2) Understanding the possible contribution of recycled fibers used as dispersed reinforcement in concrete matrices;

Objective 3) Demonstrating the feasibility and possible applications of using natural fibers as reinforcement in cementitious composites.

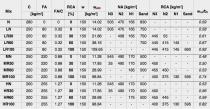

Recycled Aggregate Concrete (RAC)

A significant part of the activities involved in the EnCoRe Project is aimed at investigating the mechanical behaviour of concrete with recycled constituents. This specific class of materials would otherwise be considered as ordinary waste with a high economic and environmental value, and with significant costs for regular disposal. Particular attention is, therefore, on a partial replacement of both aggregates and cement with recycled components, such as Recycled Concrete Aggregates (RCA) and/or Fly Ash (FA). Fly ash is a fine, glass-like powder recovered as a waste from the gases created by coalfiring electric power generators. Using FA in concretes provides a double benefit: firstly, it reduces the total amount of industrial waste and, secondly, it reduces the production of Portland cement with its significant atmospheric emissions of CO2. The use of both FA and RCA in concrete production is supposed to significantly improve the mechanical properties of RCA, making them more comparable with those concretes made with cements and virgin aggregates. Starting with an ordinary concrete mixture as a reference, three groups made of four different concrete mixtures were designed and produced to investigate the effect of partial cement replacement by an « equivalent » amount of FA as a reactive pozzolan. In addition, the four mixtures in each group also have different recycled components that replace the ordinary aggregates. Table 1 provides an overview of the thirteen mixtures considered in the study.

The first group is of four RCAC mixtures where 80 kg/m3 FA was added and 30 kg/m3 was considered to act as a replacement for the Portland cement once compared with the reference mixture. The second group had 220 kg/m3 FA added, of which 30 kg/m3 is also considered to act as a replacement for Portland cement and the remaining part as a filler. Finally, the third group was prepared with an even higher FA content, i.e. 255 kg/m3, which was more than a complete replacement of the Portland cement in the reference mixture and was well beyond the limits allowed by current regulations.

Table 1. Description of the concrete mixture composition

(w=water; wadd=added water; b=binder (C + FA); bo=C+k FA, with k=0.40 according to EN206, 2006)

All mixtures were designed to obtain a minimum slump of 160 mm and, although this requirement was achieved for all of them, a significant reduction in workability was observed as a result of the recycled aggregates addition, whereas the addition of the large amounts of FA partly compensates for this reduction in workability, probably due to the rounded shape of the particles. This synergetic effect is even more apparent considering the compressive strength in the hardened state (Figure 1). From this, the mean values of the compressive strength were evaluated by testing several cubes prepared from the thirteen concrete mixes under consideration. Tests have been performed for different curing times, ranging from 2 to 90 days.

Figure 1 highlights the compressive strength evolution for samples made with mix “LN” - i.e. the natural aggregate concrete with the lowest amount of FA – which turns out to be very close to the reference mix (“N”). On the other hand, the experimental results also show that partial replacement of natural aggregates with recycled ones leads to a substantial reduction in the compressive strength of the concretes. Particularly, a closer look at experimental results from the RCA specimens showed the following observations:

a) A progressive reduction in the concrete compressive strength occurred with the increase in percentage of recycled aggregates in the mix (compare the strength values obtained for the three “LR,” the three “MR” and the three “HR” mixtures reported in the bar diagram of Figure 1);

b) Acceptable performances have been obtained for curing times longer than 28 days, in the case of RCA = 60%, and when high amounts of FA have been added to the mix (see strength values of mixes «MR60» and «HR60»);

c) Replacing 30 % of NAs with RCAs together with the addition of low amounts of FA (viz. mix «LR30») led to a concrete compressive strength comparable to the reference mix (i.e. the mix «N»); in fact, regardless of the curing times, the difference between the mean strength values of these two types of concretes did not exceed 10%;

d) The concrete strength of the mixtures with a high content of RCA could be improved by partially replacing the finest aggregate fractions with FA (compare the strengths of RCA100 % samples, i.e. mixes “LR100”, “MR100” and “HR100”).

Empirical evidence from the briefly reported experimental program confirms that recycled aggregates have a significant influence on the mechanical behaviour of RCA. The main reason for this is that the aggregates from recycled concretes show a significantly higher porosity with respect to ordinary aggregates. Such a high porosity does not only result in a more porous (and weaker) structure of the concrete matrix, but it may also cause a change in the cement hydration reaction, as it results in a potentially higher water content in the mix. Depending on the absorption capacity, a higher moisture content may affect the overall hydration process. This very fundamental modification was thoroughly investigated by observing the time evolution of the degree of hydration under adiabatic conditions obtained for concretes with ordinary aggregates and recycled ones. Particularly, a significant influence of the altered moisture condition due to the aggregates (either dry or soaked) was observed on the time evolution of the hydration reaction, which is basically unaffected by this aspect in the case of ordinary concrete.

Finally, results obtained from the experimental tests clearly demonstrate the feasibility of structural concrete with recycled constituent. Particularly, a synergetic effect of combining recycled aggregates with FA clearly emerged. Experimental results demonstrate that the limitation imposed by current codes and regulations in terms of replacement ratios could be reconsidered, when considering the almost identical performance of the mechanical performance of RCA mixtures. For this, a deeper understanding of the fundamental phenomena that drive the hydration process of RCAs is essential and will lead to an extension of the current level of knowledge on such materials, which so far have been mainly investigated under a merely empirical standpoint. The durability issues on RCAs with a relatively high percentage of cement replaced by FA should be also thoroughly investigated.

Recycled Steel Fiber Reinforced Cementitious Composites (RSFRCC)

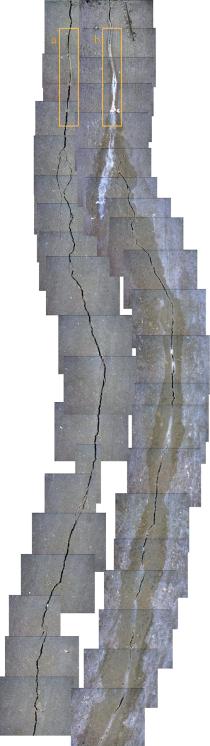

In recent years, the disposal of waste from tires has emerged as a big issue in waste management. The increasing amount of used tires actually constitutes a serious threat to the environment, as well as to human health. Moreover, based on the “Council Directive 1999/31/EC” of the European Commission on the Landfill of Waste, “whole tires” can no longer be landfilled and, since July 2006, such regulations have been applied to either “whole” or “shredded” tires. Therefore, there are strong motivations for recycling and reusing such waste materials, which can easily be turned into a wealthy source of secondary raw materials. In fact, the recycling process for used tires mainly consists of separating the internal steel reinforcement from the rubber coating. Figure 2 shows an example of steel fibers obtained from processing out-of-use tires, and, as a result of this process, they appear in a curly, twisted form, with a rather irregular length and diameter.

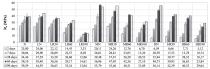

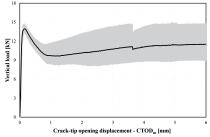

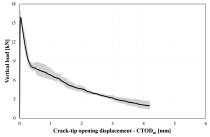

These Recycled Steel Fibers (RSFs) could possibly be employed in concrete to replace the industrial ones (ISF) that act as secondary reinforcement in a matrix of Fiber-Reinforced Cementitious Composites (FRCCs). The feasibility of this possible application has been assessed experimentally by considering a reference mix with a 0.5 % by volume addition (40 kg/m3) of Industrial Steel Fibers (ISFs) and three more mixtures replacing 25 %, 50 % and 100% of the fibers with recycled ones. Both compression and bending tests were performed on samples of the aforementioned FRCC mixtures. Particularly, four-point bending tests were carried out on pre-notched prismatic specimens, following a testing standard. The tests were carried out in a displacement control mode, while measuring the Crack Tip Opening Displacement (CTOD) and the corresponding applied load. The load - CTOD results for the tests carried out on the four different FRCC mixtures, in terms of average results (black line) and minimummaximum variation (shaded area) highlighted the significant influence of the recycled fibers (Figure 3).

The post-cracking behaviour of Fiber Reinforced Concretes (FRCs) is generally characterized by a steeper and less ductile softening branch in specimens with large quantities of RSFs substituting ISFs. The inexistence of dedicated anchorage parts in the RSFs favour the occurrence of a load decay just after crack initiation, followed by a pseudo-hardening phase of an amplitude that depends on the content and fiber properties and surrounding matrix performance. Nevertheless, it is worth highlighting that a significant increase in toughness was observed for all FRC specimens with respect to the brittle post-cracking behaviour of ordinary plain concretes. In detail, based on the experimental results obtained, the following observations can be highlighted:

a) The compressive strength is almost unaffected by the used percentage of fiber addition and no significant difference was detected between FRC specimens and the ISFs and RSFs;

b) On the contrary, the bending behaviour observed in the experimental tests was significantly influenced by the fiber reinforcement contribution;

c) In this regard, a significant change in the post-peak cracking behaviour was observed as a result of the replacements of the ISFs with an equal amount of RSFs;

d) Particularly, the higher the percentage of ISFs replaced by RSFs, the more significant the reduction in post-cracking toughness (in terms of equivalent post-cracking strengths and/or ductility indices);

e) Nevertheless, despite the low amount of fibers added (0.5% in volume), a significant increase in the equivalent toughness was observed for replacements with both ISFs and RSFs.

Natural Fiber Reinforced Cementitious Composites (NFRCC)

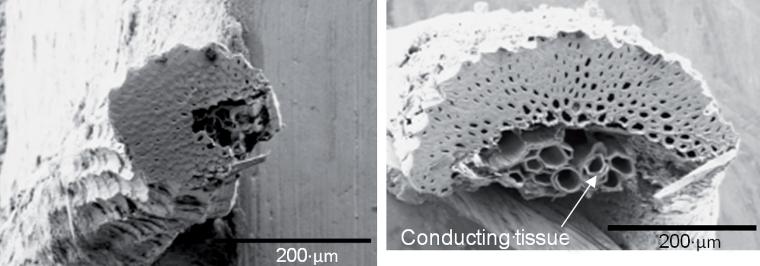

Although natural fibers can be produced from a large variety of plants, in the EnCoRe Project, focus was on sisal fibers that have been extensively studied at LabEST/UFRJ over the last few decades. Sisal fibers are extracted from the leaves of the sisal plant (Agave sisalana) showing long fiber bundles. A sisal plant produces between 200 and 250 leaves before flowering, each of which contains approximately 700–1400 fiber bundles with a length of about 0.5–1.0 m. The sisal leaf consists of a sandwich structure composed of approximately 4 % fiber, 1 % cuticle, 8 % dry matter and 87 % water. The equivalent diameter of sisal fibers is around 200 μm and the cross-section is rarely circular, but usually has an “arch” or ‘‘horseshoe” shape (Figure 4).

The chemical composition of the sisal fiber comprehends approximately 54–66 % cellulose, 12–17 % hemicellulose, 7–14 % lignin, 1 % pectin and 1–7 % ash.

The use of natural fibers, in combination with steel fibers, to produce High Performance Fiber Reinforced Cementitious Composites, has been investigated within the EnCoRe Project. Due to the large size differences between steel and natural fibers, different combinations of hybridization with steel fibers have been adopted. In order to widen the investigation, a composite with raw sisal fibers, hybridized with either cellulose nanopulp, micro-crystalline cellulose powder or eucalyptus microfibers has been studied as well. The influence of pre-saturation of raw sisal fibers has also been investigated. Because of their highly hydrophilic nature and porous microstructure, natural fibers can absorb water as well. This can happen either during the mixing process or through dedicated pre-saturation. The water accumulated in the porous natural fibers may also be released during cracking or at damaged locations where it may reactivate hydration reactions initiating a delayed self-healing process for “repairing” these cracks or damages (Figure 5).

Acknowledgements

The authors wish to acknowledge the support of the networking activities provided by the « EnCoRe » project (www.encore-fp7. unisa.it) (FP7-PEOPLE-2011-IRSES, n. 295283) funded by the European Union as part of the 7th Framework Program for Research and Innovation.

References

Almeida Melo Filho J., Andrade Silva F., Toledo Filho R.D., (2013), Degradation kinetics and aging mechanisms on sisal fiber cement composite systems, Cement and Concrete Composites, 40, 30-39.

Alves Fidelis M.E., Vitorino Castro Pereira T., Fonseca Martins Gomes O., Andrade Silva F., Toledo Filho R.D. (2013), The effect of fiber morphology on the tensile strength of natural fibers, Journal of Materials Research and Technology, 2(2)149-157.

Barros J.A.O., Zamanzadeh Z., Mendes P.J.D., Lourenço L.A.P. (2013), Assessment of the potentialities of recycled steel fibers for the reinforcement of cement based materials, Proceedings of the ACI Italy Chapter Workshop on “The New Boundaries of Structural Concrete”, Bergamo (Italy), 3-4 November 2013.

Ferrara L., Krelani V. (2013), A fracture testing based approach to assess the self healing capacity of cementitious composites, Proceedings of the 8th International Conference on Fracture Mechanics of Concrete and Concrete Structures, FraMCoS 2013, 351 - 360.

Koenders E.A.B., Pepe M., Martinelli E. (2014), Compressive strength and hydration processes of concrete with recycled aggregates, Cement and Concrete Research, 56, 203-212.

Lima C., Caggiano A., Faella C., Martinelli E., Pepe M., Realfonzo R. (2013), Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash, Construction and Building, 47, 547-559.

Toledo Filho R.D., Koenders E.A.B., Pepe M., Cordeiro G.C., Fairbairn E., Martinelli E. (2013), Rio 2016 sustainable construction commitments lead to new developments in recycled aggregate concrete, Proceedings of the Institution of Civil Engineers. Civil engineering, 166(6), 28-35.